Good quality

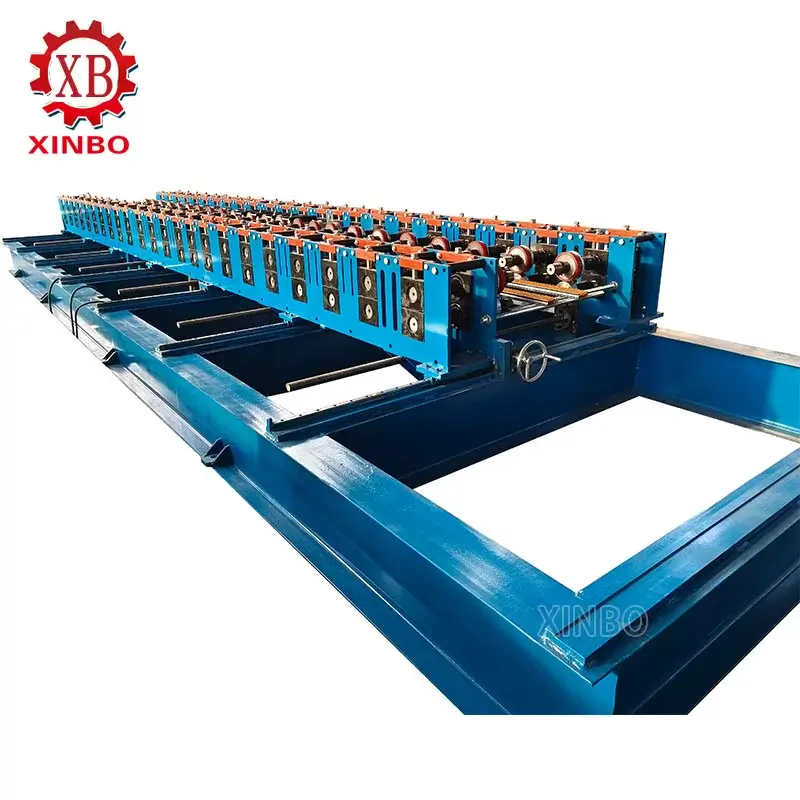

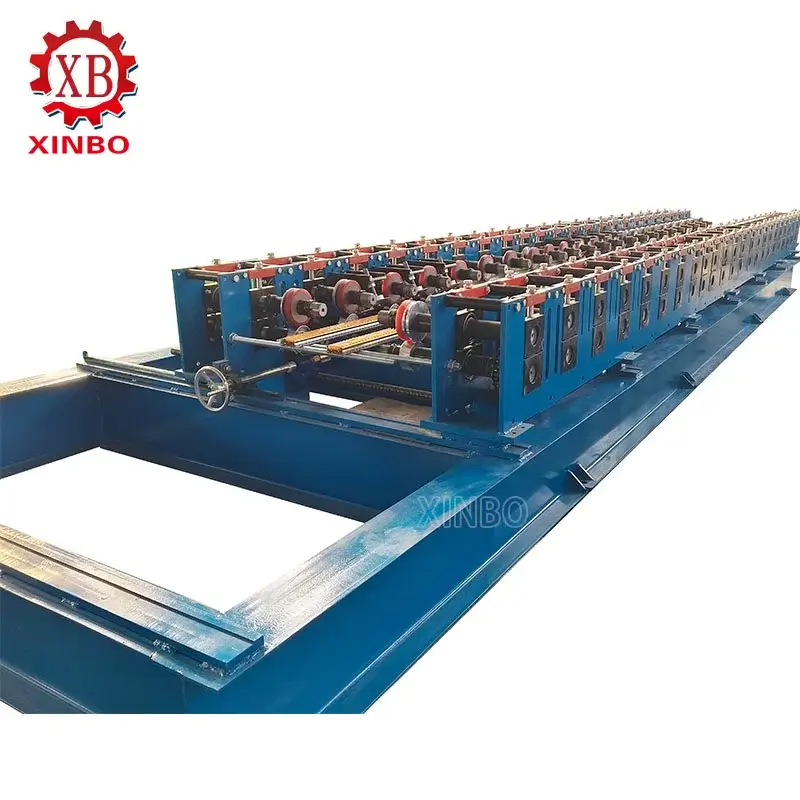

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→In the modern day of manufacturing, there is focus on efficiency and flexibility in trying to be in a place to compete. Businesses always seek alternative ways of making their production both cost-effective and efficient. One of these machines that has become popular is the Automatic Changing Width Panel Machine, where you can make different widths of panels because of automatic changing.

These types of automatic panel changing width machines are as automatic and as versatile as they can be, and well worth the investment to panel producing businesses. With so many to select from, though, how do you know which one is best for your specific application?

Before you head out and buy one of these machines, it is beneficial to learn a little bit about what they are and how they operate.

An Automatic Changing Width Panel Machine is a highly technical machine that is employed in the manufacturing of panels of varying widths with little manual intervention. It has an auto system in a way that rolls and cutting dies of the machine get automatically replaced depending upon different sizes of the panel.

The largest advantage of such machinery is that these types of machines are able to shift easily from the size of a panel width to another one with very accurate accuracy, thereby saving time and also making overall production a quality one. These kinds of machines are the backbone machines of modern metal fabrication plants because they possess automated features, which reduce labor cost and boost production.

Purchasing an Automatic Changing Width Panel Machine can benefit your business in the following ways:

Increased Efficiency: Automated changes reduce manual changes, thereby shorter production cycles and more production.

Lower Labor Cost: Automation has fewer operators, conserving labor cost and freeing personnel for other uses.

Improved Accuracy: Computer cutting provides accurate panel sizes, with no waste and mistake.

Greater Flexibility: From flexible panel width adjustment for easy adaptation with different customer orders and project specifications.

Material Flexibility: The majority of the machines are capable of working with various materials like PPGI, GI, and AI, and that gives flexibility to your production.

The perfect Automatic Changing Width Panel Machine involves a serious thought of the following:

PLC Control: PLC is the brain of the machine, which is utilized to control various automated operations. Select a system from a reputable company (e.g., Siemens, Schneider) for their reliability.

Touch Screen Interface: The touch screen interface is convenient and enables the entry of production data such as batch size, length, and quantity.

Encoder: An encoder provides precise feedback of the material position and speed to provide the correct cutting lengths.

Automatic Adjustment: The most astounding aspect of these machines is that they automatically change the width of the panel that is being produced. Observe how quick and easy this process is.

Customization Options: Some companies offer customization options to suit the machine according to your individual requirements. This may be a modification in the roller system, cutting system, or control system.

OEM Availability: In case you need special specifications or want to install the machine on a current line, ask if the OEM (Original Equipment Manufacturer) service is offered by the manufacturer.

Experience: Choose a supplier with experience in exporting and manufacturing roll forming machines. Make sure the suppliers are high in experience and have good customer rating.

Certificates: Make sure the supplier is certified by certificates such as CE and ISO9001 that guarantee they are compliant with quality and safety.

After-Sale Service: After-sales service quality is important. Make sure the supplier offers full warranty (e.g., 24 months) and technical service for the machine’s entire lifetime.

Training and Installation: Assure the training and installation service capability of the supplier so you can make the machine operational at once.

Customer Service: Assure that the supplier has quick and available service in terms of answering your question and complaint.

Xinbo offers roll forming machines of high quality with customized design options. Xinbo machines are manufactured according to international IEC standards. Xinbo offers rapid lead times for shipping and testing of every machine for quality. Xinbo machines are latest. Select Xinbo for your automatic width changing panel machine needs.

Choosing the best Automatic Changing Width Panel Machine for your business is a significant decision that requires careful evaluation. By considering the factors outlined in this guide, you can make an informed choice that aligns with your specific needs and budget. Investing in the right machine can significantly enhance your production capabilities, reduce costs, and improve your competitiveness in the market. The Automatic Changing Width Panel Machine will allow you to form different width of panel by changing automatic.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→