Buy China’s Best Antiskid Plate Steel Embossing Press Machines? Here’s What to Consider!

In today’s industrial world, accuracy and safety matter most. Antiskid plate steel embossing press machines are key. They shape how industries make top-notch, non-slip surfaces. From building projects to shipyards and factory floors, embossed steel plates have wide, vital uses. This blog walks you through what to think about when picking the best machines from China. It helps you choose wisely based on main features, tech details, and lasting worth.

Why Antiskid Plate Steel Embossing Press Machines Matter in Modern Industry

Antiskid plates are integral to several industries because they provide enhanced safety and durability to surfaces that are frequently exposed to heavy traffic or harsh environments. These embossed steel plates feature raised patterns that prevent slipping, even in wet or oily conditions. As such, they are indispensable in construction, shipbuilding, and industrial flooring, where safety is a primary concern. The embossed patterns can vary from simple designs to more intricate patterns, each designed to maximize friction and reduce the likelihood of accidents.

In construction, antiskid plates cover stair steps, paths, and platforms. In shipbuilding, they line ship decks where wet surfaces are common. For factory floors, embossed steel keeps workers steady. It lowers slip risks on plant floors, docks, and storage areas. Stricter safety rules, like OSHA’s, have raised the need for these strong, quality materials.

The Growing Demand for Precision Embossing

As safety and toughness needs grow, so does the call for precise embossing tech. Big building projects and OSHA awareness have spiked antiskid plate use. Plus, rust-proof designs have made exact embossing even more vital. Well-made patterns keep plates non-slip over time. This holds true in harsh weather or corrosive settings.

In a tough market, makers and builders aim to meet rising needs. They want plates that ensure safety and handle industrial wear. Here, advanced Antiskid Plate Steel Embossing Press Machines shine. They’re built for top accuracy, speed, and material fit.

Key Features of High-Quality Antiskid Plate Steel Embossing Press Machines

When picking an antiskid plate steel embossing press machine, look at several traits. These ensure you get gear that fits your needs.

Precision and Consistency in Pattern Replication

Accuracy is the heart of any embossing tool. This is extra true for antiskid plates. The machine must copy detailed designs evenly across big steel sheets. Top machines often use CNC (Computer Numerical Control) setups. These guarantee patterns hit with perfect precision. Also, laser-guided systems help place designs just right. They cut down on uneven spots.

Take big steel sheets, for example. Getting the same tread depth all over matters. A machine with great pattern copying keeps every bit of the plate non-slip. This ensures it works and stays safe.

Material Compatibility and Thickness Range

A standout trait of a good embossing press is its range. It must work with carbon steel, stainless steel, and galvanized plates. Thickness can span 1mm to 3mm. The machine should handle different grades without bending or breaking during embossing.

This flexibility meets varied industry needs. Construction might need thick plates. Shipbuilding may lean on rust-proof materials. The machine should adapt to both thin and thick plates. It must deliver solid results every time.

Speed and Production Capacity

Speed counts when choosing an embossing press. Big jobs—like factory flooring or construction—need fast cycle times. Quality can’t drop, though. Smaller or custom runs may need a machine that bends on speed but holds precision.

The best machine balances speed and quality. It offers high output without messing up the pattern. Handling both big runs and custom jobs makes it a handy tool for builders.

Technical Considerations When Choosing a Machine

Picking the right embossing press means knowing the tech side. These points affect how well it runs, how long it lasts, and if it fits your needs.

Hydraulic vs. Mechanical Press Systems

Embossing presses use hydraulic or mechanical systems. Hydraulic ones suit complex patterns needing strong force control. They’re flexible and handle detailed designs with different depths. They work better for thicker stuff too. They spread pressure evenly.

Mechanical systems fit fast, repeat designs. They’re quicker and sharper for making the same pattern over lots of material. But they might not match hydraulic precision or flex for tricky designs.

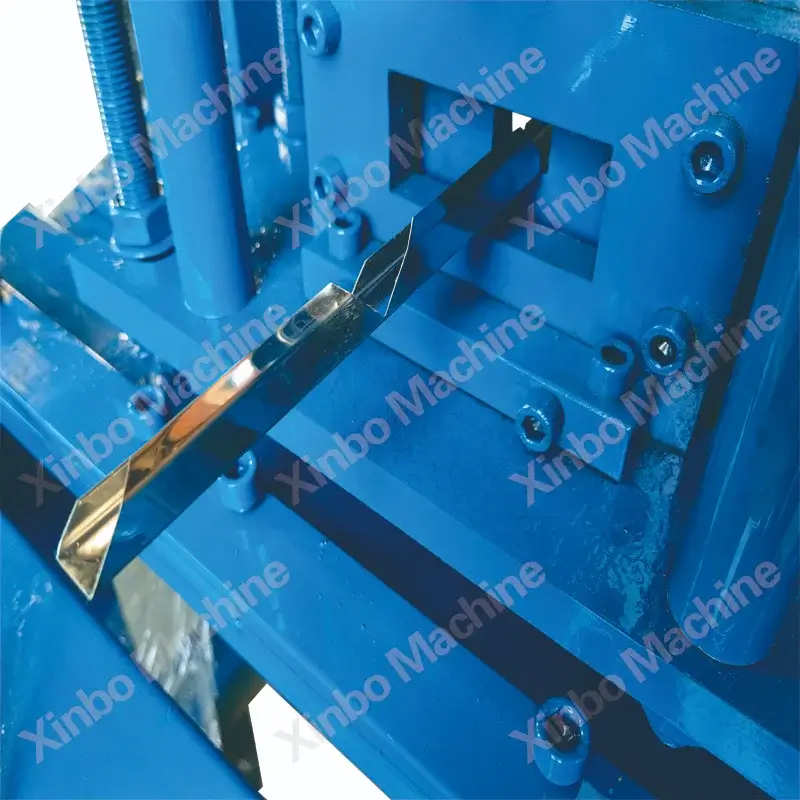

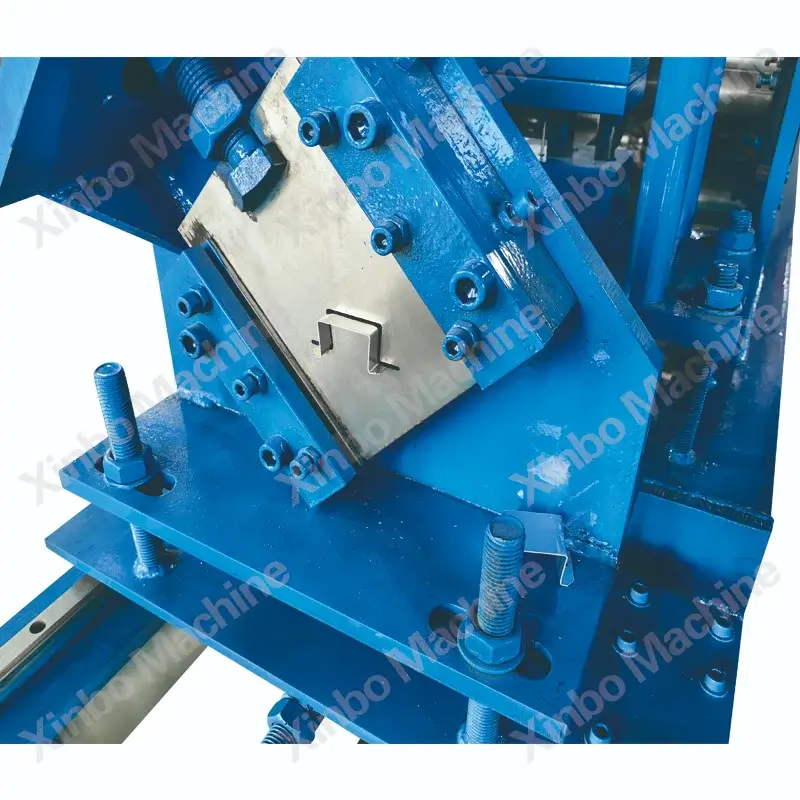

Die Design and Customization Capabilities

Customization matters in embossing presses, especially with dies. Modular dies let makers stamp different designs on one machine. This makes it handy for many uses. Heat treatment can stretch die life too. It keeps the machine running without frequent swaps.

Energy Efficiency and Sustainability

Energy saving is a big deal in today’s making world. Servo-driven systems cut power use while keeping strong output. Plus, modern machines aim for green goals. They recycle scrap metal from embossing. This trims waste and lowers running costs over time.

Evaluating Total Cost of Ownership (TCO)

When buying an embossing press, think about total cost of ownership (TCO). This covers more than the starting price. It includes upkeep, energy use, and worker costs too.

The upfront cost might seem steep. But a machine with precision, energy saving, and toughness can save big later. For example, top machines cut material waste with steady pattern work. This boosts your return on investment (ROI).

Maintenance Requirements and Downtime Risks

Keeping your embossing press in shape is key to a long life and less downtime. Regular oiling, part swaps, and predictive tools help it run smooth. Predictive tools spot issues early. They lower the chance of sudden stops.

XinBo Antiskid Plate Steel Embossing Press Machines Customization Service

XinBo crafts custom embossing options. We tweak machines for unique designs, material types, and output sizes. Our setups include live pressure adjustments and IoT tracking. This ensures top results for special jobs.

Future-Proofing Your Investment

The future of making leans on smart tech. IoT sensors bring live pressure and heat checks. They lift precision and efficiency. AI pattern tweaks cut trial runs. This speeds up production.

As industry rules shift, your gear should too. Upgradable software keeps your embossing press in line with new methods and safety marks like ISO and CE. Future-proofing your buy keeps it ready for fresh challenges.

Frequently Asked Questions (FAQs)

Can Antiskid Plate Steel Embossing Press Machines handle curved surfaces?

Yes, our machines have adjustable rollers and 3D die setups. They work on curved surfaces fine.

How does humidity affect embossing quality?

With climate-controlled systems, our machines stop rust during work. They keep quality steady in damp settings.

What safety features are critical for operator protection?

Our machines come with light curtains, quick stops, and auto sheet feeders. These boost worker safety.

Ready to Elevate Your Antiskid Plate Production?

XinBo specializes in customizing antiskid plate steel embossing press machines, designed for precision and durability. With tailored solutions for varied production needs, XinBo ensures efficient embossing processes, enhancing the performance and quality of antiskid plates. Our machines provide robust, reliable, and optimized manufacturing for your production line. Contact us today to discuss your customization needs and elevate your production efficiency!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia