Breaking Down Costs with Metal Roll Forming Machine Manufacturers

Exploring Metal Roll Forming Machines

Metal roll formers are now a part of today’s construction and manufacturing methods. They focus on making metal roof sheets and structural parts with accuracy and speed. These machines use rollers to shape metal sheets into forms making the fabrication process, in construction efficient. The key to the success of metal roll formers is their flexibility in handling designs and requirements making them crucial, for manufacturers looking to cater to a range of client demands.

Significance and Applications

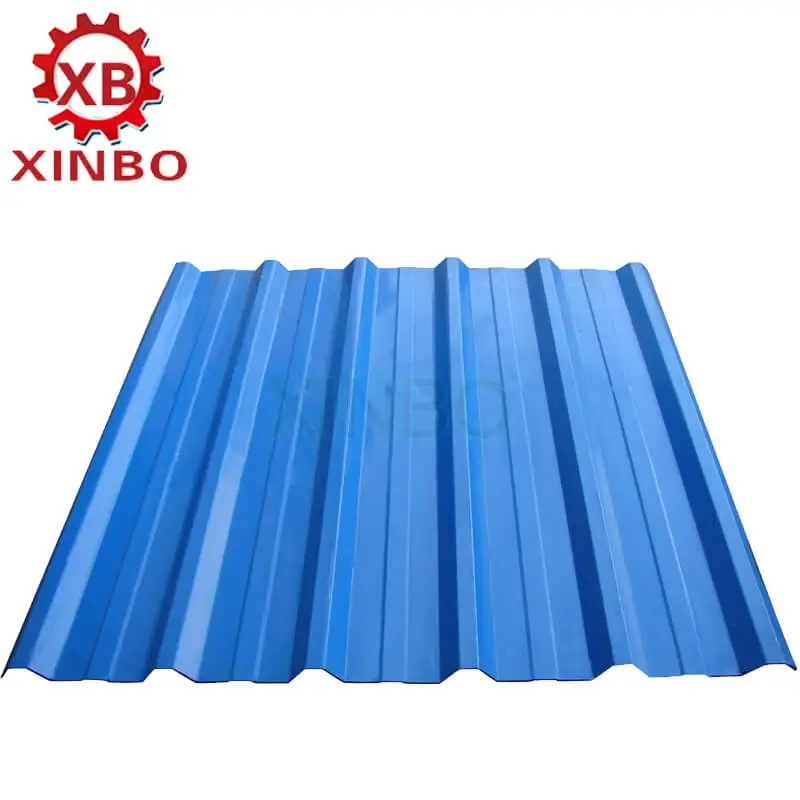

Metal roll forming equipment is crucial, in the field of construction as it is widely utilized to craft metal roof sheets and vital structural elements like purlins. Customized building materials that are durable and visually attractive are in demand these days. This equipment caters to this demand efficiently. These machines are not limited to the construction industry; they also find use in sectors, like automotive and machinery where specific metal shapes are necessary. The adaptability of these machines allows them to keep up with the changing needs of construction ventures.

Advantages Over Traditional Methods

When you look at metal roll forming machines, versus the fashioned metal fabrication techniques there. Well, let me tell you. There are some real perks to using these machines! One thing that stands out is how precise they are in creating top-notch products that just click into place smoothly when it’s time to put them together. And get this. With the roll forming process being automated like it’s on these machines. You can say goodbye to a lot of human errors messing things up and slowing things down! It’s like having your little efficiency buddy there beside you. Not that metal roll-forming machines keep the production line running nonstop. Manufacturers can churn out big batches in no time flat! That means saving a bundle, on labor costs and getting bang for your buck every step of the way. Metal roll forming proves to be an option compared to traditional manufacturing methods due, to its precise and efficient operation.

Key Considerations When Choosing Metal Roof Sheet Machines

When choosing a metal roof sheet machine for your projects it’s important to consider factors to ensure it works well. Fits the project requirements effectively.

Durability and Material Quality

The lifespan of a metal roof sheet machine mainly relies on the materials. Design is crafted from using high-quality steel resulting in better durability and dependability, for continuous use purposes. It’s also essential to assess the capability of the machine in handling metal types and thicknesses as it impacts its flexibility and suitability, for project needs Manufacturers should prioritize machines with a strong history of reliability and longevity to reduce downtime and maintenance expenses.

Energy Efficiency and Cost-Saving Benefits

Considering energy efficiency plays a role, in deciding which metal roof sheet machines to buy as it can help cut down on electricity usage and save money in the run. Additionally, machines equipped with technologies like speed drives and improved insulation can bring down operational costs significantly even though the initial cost for such energy-efficient machines might be higher. Despite the investment the ongoing savings usually make it a wise decision, for both manufacturers and construction firms.

Speed and Efficiency in Production

The rate at which a metal roof sheet machine functions plays a role, in the productivity and profitability of a manufacturing operation. Machines that provide production speeds with quick setup times enable manufacturers to meet deadlines and handle orders while maintaining quality standards. In an industry environment like this one efficiency is key; companies that opt for performing machines stand to gain a competitive edge, over their rivals. When assessing machinery options it’s important to take into account both the production capacity and speed to ensure they can effectively meet demand.

Cost Analysis with Metal Roof Sheet-Making Machines

For companies thinking about investing in metal roof sheet manufacturing equipment conducting a cost evaluation is essential.

Upfront Investment vs Long-term Savings

The initial expense of purchasing a metal roof sheet manufacturing machine may seem high at a glance. It’s crucial, for prospective buyers to consider this upfront cost in comparison to the expected long-term benefits it brings along with it. For companies that heavily depend on metal roof sheets for their building ventures will notice a decrease in both material and labor expenditures due to the production process and reduced wastage facilitated by these machines. Moreover, the lasting performance and effectiveness of machines contribute towards an extended operational life span which ultimately results in a more profitable return on investment, over time.

Maintenance and Operational Costs

It’s important to factor in the maintenance and operational costs when evaluating the impact of owning a metal roof sheet machine in the long run. Routine upkeep is key, to keeping it running smoothly and lasting longer. Even though certain machines may be upfront initially; if not properly maintained they could end up costing more in repairs. Upkeep down the line. So it’s wise for businesses to look beyond the buying price and also factor, in the estimated maintenance and operational expenses when deciding what to go for.

Return on Investment: A Quantitative Perspective

Determining the return, on investment (ROI) for metal roof sheet manufacturing equipment requires assessing aspects such as productivity levels, energy expenses, and manpower efficiency. By examining these factors companies can gain insight into when they will recover their capital. Usually, businesses that streamline their production methods and use machinery can anticipate a ROI, within a reasonable timeframe. It is essential for manufacturers to regularly review their procedures to make sure they are maximizing the advantages of their investments.

In summary, choosing the metal roll-forming equipment and grasping its related expenses necessitates an evaluation of several aspects such, as longevity, power efficiency, and overall manufacturing capacities. Through an examination, companies can make choices that are in line, with their future objectives ensuring they stay competitive in the ever-evolving construction industry of today.

Introducing XINBO MACHINE MAKING CO. LTD

Company Overview and History

Established with a dedication, to deliver top-notch products and services XINBO MACHINE MAKING CO., LTD has built a presence in the manufacturing sector by focusing on cutting-edge metal roll forming technologies. Adapting to the changing demands of customers over time the company offers state-of-the-art machinery that boosts production efficiency. Known for its commitment, to excellence and accuracy XINBO has earned a reputation as a provider of metal roll-forming machines. Throughout its journey, the company has consistently. Stayed dedicated, to providing top-notch machinery that plays a role in the achievements of its collaborators.

Range of Products Offered by XINBO

High Precision Metal Roll Forming Machines

XINBO provides a selection of top-notch metal roll-forming machines tailored to meet manufacturing requirements effectively. Their machinery incorporates state-of-the-art technologies to guarantee the shaping of each part, with measurements and tolerances. This precision is crucial in scenarios where the strength and stability of structures are critical like, in the development of industrial edifices. Additionally, these systems are designed to handle materials enabling manufacturers to transition between products without compromising quality.

The versatility of Metal Roof Sheet Making Machines

XINBO offers a variety of metal roof sheet manufacturing machines that showcase flexibility, in their capabilities. These machines are designed to manufacture a range of metal roof shapes to help customers efficiently fulfill project needs. The capacity to produce designs using one machine greatly boosts efficiency. Proves to be a valuable tool, in construction projects. Moreover, XINBO guarantees that their roof sheet-making machines can work with types and thicknesses of metal expanding their use across industries.

Customization Options for Specific Needs

XINBO offers a range of customization options, for its metal roll-forming machines to meet the needs of each client. With the assistance of the XINBOs engineering team, customers can personalize machines to suit their requirements. This adaptability improves efficiency. Boosts productivity by enabling businesses to quickly adapt to market shifts. Moreover, tailored machinery can enhance resource management by minimizing waste and promoting sustainability, in manufacturing operations.

How XINBO Ensures Cost Effectiveness

Innovative Technology Integration

The dedication, to innovation at XINBO shines through in its incorporation of state-of-the-art technology in its machinery designs. By utilizing automation and the Internet of Things (IoT) XINBO empowers real-time monitoring and enhancement of production processes. This integration results in precision. Reduced downtime while boosting operational effectiveness. All leading to cost reductions for manufacturers. Additionally, the use of technology gives clients access, to production metrics helping them make decisions based on real-time data and fostering ongoing enhancements.

Sustainability Initiatives and Their Economic Impact

XINBO puts an emphasis on sustainability, in its operations by taking steps to minimize the environmental footprint of its manufacturing processes. The company focuses on creating machines that are energy efficient and generate waste to support clients in reaching their sustainability targets while also reducing operational expenses. Moreover, XINBOs use of materials in machine construction aligns with the growing trend towards eco-conscious manufacturing practices giving customers who value environmental sustainability an edge, in the market.

Value-Added Services: Training and Support

In addition, to offering cutting-edge equipment solutions XINBO sets itself apart by providing training and support services. Recognizing the importance of mastering the use of machinery for excellence XINBO offers training courses, for its customer’s workforce. This training covers machine handling techniques, maintenance procedures, and safety guidelines. By equipping employees with skills XINBO boosts the effectiveness of production processes while minimizing the risk of operational errors that could result in downtime or extra expenses.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia