Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→Pipe forming and pipe welding machinery is important in many industries like manufacturing and construction. In the construction sector, machines determine the support structures of buildings, bridges, and other constructional structures. They produce the pipes that serve as the support structures in skyscrapers and bridge support structures to enable them to support environmental stresses and loads.

The precision and quality of the welding and forming processes are decisive to the performance, safety, and longevity of the finished product. It would be virtually impossible to achieve the current production demands without machines.

Xinbo is at the forefront of pipe welding and forming machines. With its state-of-the-art technology, high-standard products, and stable working operation, Xinbo offers wholesalers, retailers, and bulk buyers appropriate machines based on their needs. Composing a series of machines to deal with various applications, from light to heavy duty, Xinbo offers efficient pipe processing solutions that are high-tech and innovative.

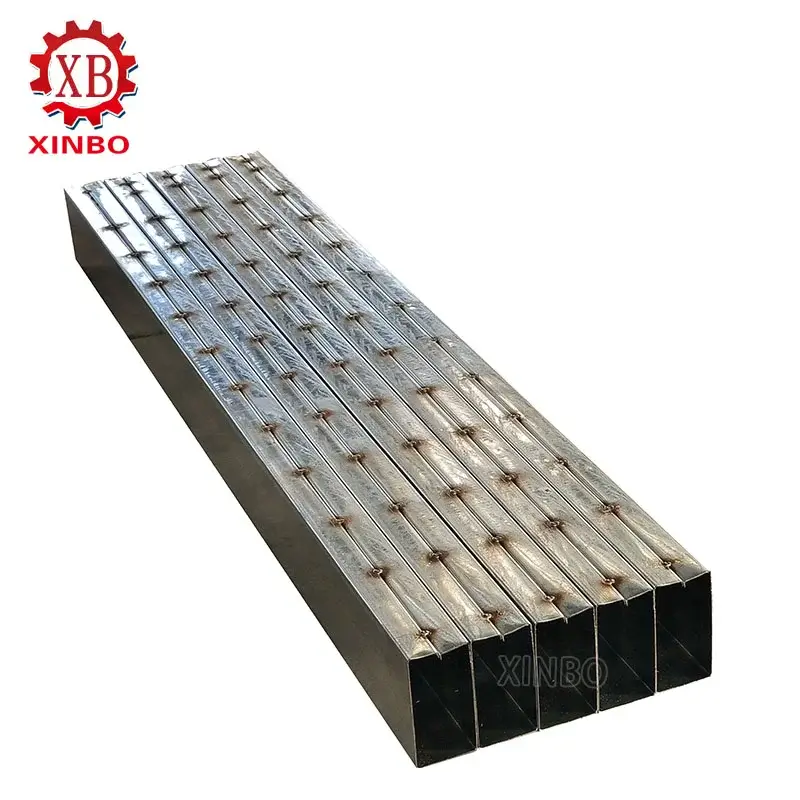

The machine fabricates various galvanized steel plates to provide rust-free pipes for tough weather environments. Its advanced welding technology maintains the integrity of the galvanized coat, ensuring that the pipes are suitable for open-air fences, roof brackets, and industrial piping. The precision of the forming rollers and welding guarantees uniform quality pipes with silky surfaces and constant wall thickness.

High-Frequency Welded Pipe Machine (ERW Tube Mill Machine) Xinbo’s ERW Tube Mill Machine uses high-frequency electromagnetic induction to rapidly heat steel strip edges, creating stable, seamless welds. It is a high-speed manufacturing machine with tight diameter and wall thickness tolerances of manufactured pipes. The advanced control system ensures stable operation, which makes it very suitable for use in the auto market and oil and gas pipelines with high pressure.

Stainless Steel Pipe Fabrication Machine Designed especially for stainless steel pipe fabrication, the machine maintains stainless steel’s high corrosion resistance without losing it. Polishing and finishing tools are included in the machine, which contribute to the beauty and durability of the pipes. Pipes produced by such machines are typically utilized in food processing, drug production, and high-end architectural applications.

Tougher build for long-term performance Xinbo machines are built using high-strength steel to ensure stability and strength throughout usage. Their steel construction is not susceptible to deformation and stretching, and the rollers, welding heads, and drive trains are built using high-quality materials to minimize wear and maintenance needs.

High Speed Welding (e.g., GMAW) Xinbo’s application of sophisticated welding processes like Gas Metal Arc Welding (GMAW) ensures high welding speed and good welds. GMAW is precise, having repeatable heat input and lower impurities in the weld and hence offers superior mechanical properties and high bond strength. The flexible process ensures joining a variety of metals and alloys and, therefore, suitable for different applications.

The process is made more accurate with machine-powered rollers with certain tolerances. The rolls convert steel sheets into round pipes or square pipes by strict dimension monitoring stepwise. Xinbo machinery has advanced systems of monitors to automatically reinitiate the process if any fault or deviation within given parameters is detected and the tubes formed are better.

Xinbo Round Square Pipe Forming and Welding Machines are power- and energy-efficient in design. The power output of different models differs, ranging from 30-50 kW for light models to 100-200 kW for heavy-duty and large-capacity models. Some of the reasons behind their energy efficiency include the use of high-end servo-motor systems, which effectively regulate machine movement and conserve energy, particularly under variable speed. Besides, Xinbo’s energy-saving control systems adjust power input automatically based on workload, reducing energy consumption during slack periods.

Energy-efficient design provides cost savings in the long term. Reduced energy consumption translates into reduced electricity costs, which benefits companies with continuous machine operations throughout the day. This renders the production process cleaner and greener and makes products more competitive in the market.

Xinbo has a variety of machines to suit different business scopes. Small-scale producers can have models that can make 50-100 meters of pipes per hour. These machines are ideal for small-batch production, such as local construction of buildings or special small factory pipes. Medium-scale businesses can invest in machines that have a capacity of producing 100-300 meters per hour, which they can utilize for producing pipes for medium-scale development projects. Large-scale producers would employ high-capacity machines that have the capability to produce as much as 500 meters per hour, sufficient to supply pipes for gigantic infrastructure projects such as industrial parks or skyscrapers.

Xinbo’s machinery is very versatile and can produce round and square pipes of different sizes. Round pipes can be produced with diameters ranging from 10 mm to 300 mm, and square pipes ranging from 10 mm × 10 mm to 200 mm × 200 mm. The pipes are used in plumbing, construction, and machinery sectors.

Xinbo’s products are built with utmost precision. Pipes are built with round dimension tolerances of ±0.1-0.3 mm, and the sides of square pipes are toleranced to ±0.1-0.3 mm while the corners are still perpendicularity less than 0.5 degrees. Through such accuracy, the pipes are comfortably integrated into projects and are up to high industry standards.

Xinbo machines produce pipes that are used in structural members like scaffolding, columns, and beams in construction. The pipes, depending on their precise size and resistance to corrosion, have useful applications in skyscrapers and exposed scaffolding in building to improve safety.

In manufacturing industry, Xinbo machines produce pipes that are utilized widely on equipment components like pump casings and connecting pipes. Square pipes are a key material in furniture production for table frames, chair frames, and shelf frames. Xinbo machines give the ability to mass-produce different pipe sizes and thicknesses, which gives manufacturers design freedom and quality consistency.

Xinbo has a good reputation, with good service of many clients from different industries. Most construction firms are dependent on Xinbo equipment to carry out high-capacity infrastructure projects, like high-rise buildings, where the equipment has delivered high-quality results. Apart from that, furniture factories have enjoyed using Xinbo’s durable machines for more than a decade to produce jaw-dropping volumes of durable furniture frames.

Xinbo has good after-sales and customer service, e.g., thorough training, speedy repair, and maintenance schedules to provide maximum-long-term equipment performance. Downtime is kept at a minimum and equipment life is extended.

Xinbo Round Square Pipe Forming and Welding Machines possess superior virtues like energy-saving, large output, and accuracy. They are favored most by manufacturers and builders because of their stability and flexibility. With good customer service support, Xinbo offers a long-term business solution for high-quality pipe-forming machines.

If you are looking for a trusted source of Round Square Pipe Forming and Welding Machines, then your search ends here. Contact us today and learn more about our products and how we can assist you with tailored solutions based on your requirement.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→