Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→In today’s fast-paced construction environment, efficiency and precision are crucial. For projects involving metal studs and tracks in ceiling frameworks, double head stud and track ceiling machines have become a revolutionary solution. These machines offer a significant advantage over traditional manual methods, facilitating faster installations, improved accuracy, and increased overall productivity. In this blog post, we will delve into the benefits, essential features, and considerations when choosing the right double head stud and track ceiling machine for your needs. We’ll also spotlight Xinbo’s exceptional offering in this category.

Double head stud and track ceiling machines have quickly gained favor in the construction industry due to their ability to provide a range of benefits that directly improve the speed, accuracy, and efficiency of the installation process.

The primary benefit of double head stud and track ceiling machines is their ability to install studs and tracks simultaneously using two heads, drastically reducing installation time compared to single-head machines or manual labor. This enhanced productivity allows companies to complete projects faster, taking on more jobs and reducing turnaround times. According to a 2023 industry report from IBISWorld, the demand for automation in construction has surged, driven by labor shortages and increasing project complexity. Machines like the double head stud and track ceiling machine are a direct response to this demand, allowing businesses to maintain quality and speed while keeping costs down.

Accuracy is critical in ceiling installation, where precise alignment of studs and tracks is essential for ensuring structural integrity and visual appeal. The dual-head design of these machines guarantees that both sides of the frame are installed with consistent precision, minimizing errors and misalignments. According to construction experts at the American Society of Civil Engineers (ASCE), reducing misalignments can save up to 25% of the labor costs associated with rework. This accuracy results in a higher-quality finished ceiling and fewer mistakes during installation, reducing costly callbacks and rework.

The automation afforded by double-head machines directly translates into reduced labor. Since the machine does most of the work automatically, not as much manpower is required on site. Labor is one of the highest costs in construction, so any savings in that area could be a huge deal. According to McKinsey’s 2022 report on construction productivity, automation in construction can cut labor costs by as high as 30% in specific areas, especially for repetitive tasks like stud and track installation.

Safety is always a top priority at a construction site. In this respect, double head stud and track ceiling machines come installed with numerous safety features: emergency stop buttons, safety guards, and automated operation modes that limit the operator’s involvement to a minimum, which reduces the risk of injury. Automation of tasks in construction may substantially reduce accidents caused by manual handling and repetitive motion, according to OSHA.

Besides that, the double head stud and track ceiling machines are not confined to one project or type of material. Most of the models allow setting various sizes of studs and tracks, material types, and ceiling heights. This makes them very versatile and fit for a wide category of undertakings in the installation of ceilings-both commercial and residential. Some machines have options for customization which can be adapted to various needs, such as ceilings with complicated configurations or whenever different material thicknesses are required.

When it comes to choosing a double head stud and track ceiling machine, some features are very important to ensure the machine will meet your expectations. Let’s take a closer look at what the key factors are to consider:

The machine capacity decides the maximum size and weight of studs and tracks the machine will be able to manage. Analyze the average dimensions in your ceiling installation projects and select a machine with regard to them. For example, if one develops a machine for big and heavier projects of commercial nature, then that should be able to deal with wider tracks and thicker studs than a machine made for residential use.

The operating speed of a machine will determine the level of productivity. Choose machines that boast higher operating speeds and better design to make the process easier and faster. For instance, modern double head stud and track ceiling machines are designed to operate uninterruptedly at high speeds without compromising precision. According to experts dealing with construction machinery, the potential to handle up to 15 meters per minute can raise the output by over 20 percent compared to the older ones.

Since the nature of ceiling installations is of the highest accuracy, ensure a machine offering high-precision features is used. Some machines offer features that include variable angle cuts, measurement encoders, and precision alignment systems. This ensures studs and tracks will always be in the right place, contributing to the overall quality of the ceiling framework.

Ease of use is another important factor. A machine with an intuitively designed control interface, preferably with button and touchscreen operation, will make the process simpler. Equally important to minimizing downtime for maintenance: it should be easy to maintain, and spare parts should be readily available. A well-designed machine cuts down operational errors, enhancing the timeline of a project accordingly.

Any construction requires machines that can put up with harsh working conditions and still have the potential to work effectively. Double head stud and track ceiling machines should be made from hardy materials such as hardened steel and rollers that are of high quality for longevity purposes. A machine that is reliable can put up with daily rigors of work hence reducing breakdowns and decreasing the frequency of repairs.

Again, a very important but partially earlier-alluded-to aspect involves safety; with machines incorporating blade guards, anti-vibration features, and emergency stop buttons, operatives will remain safe even on very busy occasions, avoid injuries that at times stretch the general execution time drastically.

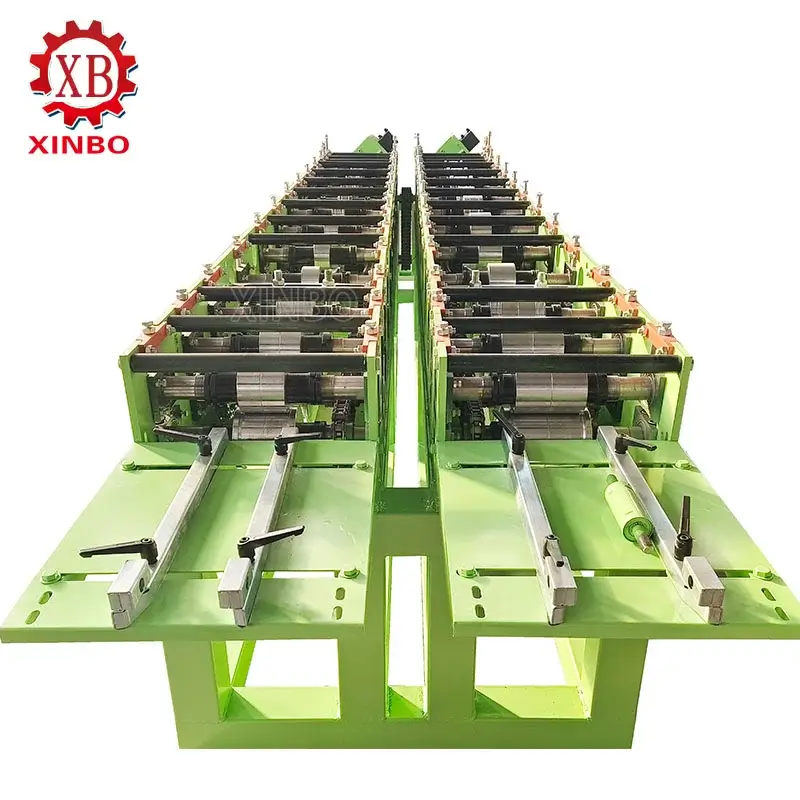

Xinbo‘s Double Head Stud and Track Ceiling Machine presents the latest in efficiency, accuracy, and versatility. For both residential and commercial construction projects, the machine is designed to offer a wealth of features that make the easy installation of metal studs and tracks for ceiling frameworks possible.

Key Specifications of Xinbo’s Machine:

-Processing Material: GI coils

-Input Width: Customizable

-Formed Width: As required

-Processing Thickness: Standard: 0.3—0.6mm

-Frame Style: Square pipe welded frame

-Material of Rollers: 45# steel, with heat treatment and hard chromed

-Diameter of Shaft: 40mm

-Production Speed: Standard: 0–15m/min (customizable)

-Roller Driven: Chain Transmission

-Cutting Model: Hydraulic Profile Cutting

-Length Measurement: Encoder

-Control Style: PLC

-Operation Model: Button+Touch Screen

-Total Power: 3+3KW (customizable)

-Voltage: 380V, 50Hz, 3 phases (customizable)

Key Features:

-Two-in-One Design: Saves valuable workspace while improving efficiency.

-Easy Operation and Usage: The user-friendly design and intuitive controls simplify operation and reduce training time.

-Automatic Running: Automates the stud and track installation process, reducing laborand increasing overall efficiency.

Xinbo’s double head machine is very reliable; it easily integrates into high-demand construction projects. Besides, Xinbo provides ODM services for customers to have the machine designed to their specifications.

Quality and Compliance: Xinbo’s machines meet the international IEC standards so your equipment are not only efficient but also are put to construction regulations across the world.

The Double Head Stud and Track Ceiling Machine from Xinbo is for any business seeking to raise the bar in productivity and reduction of labor costs, with increased installation accuracy. Be it a residential or commercial project, this machine has proven to be reliable with precision and speed to keep pace with the demands of modern construction.

Contact Xinbo today to learn how their Double Head Stud and Track Ceiling Machine can transform your ceiling installation projects with more cost-effective and productive operations.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→