Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

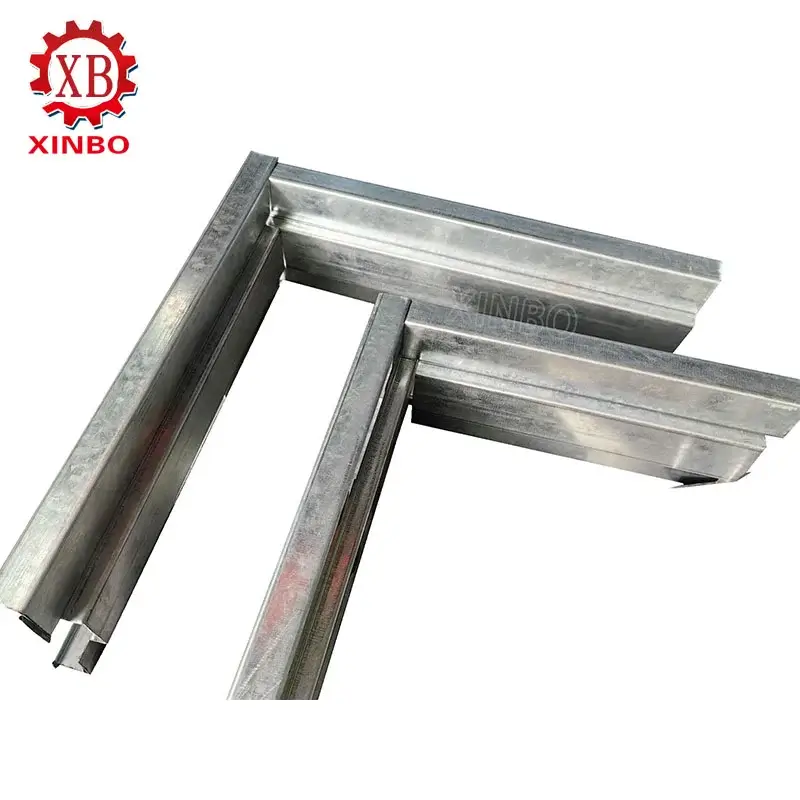

VIEW MORE→It is about precision in all details, especially when it comes to building professional doors. To make perfectly mitered joints, one needs to cut two pieces of material exactly at 45-degree angles and then put them together, which would become one perfect corner. The traditional ways of achieving this result are with a handsaw or miter box, but those are not as effective regarding accuracy or speed as 45-degree cutting machines.

These specialized machines make the work quite consistent, reducing the time taken to make accurate cuts by a huge margin. In this blog post, we look at the benefits, key features, and how to choose the best 45-degree cutting machine for your door frame production needs, with a particular focus on the cutting-edge machine offering by Xinbo.

The 45-degree cutting machines have several key advantages in comparison to manual methods on precision cuts for door frame fabrication. These are as follows:

The most obvious advantage of the 45-degree cutting machine is its precision. Those are designed to make just perfect mitered cuts so that your joints will perfectly fit into place. Such precision excludes any possibility of gaps or misalignment common with hand tools; this means stronger, professional-looking door frames.

According to the findings from Woodworking Machinery & Supply (2021), automated equipment in cutting improves the percentage accuracy of cutting up to 30-40% compared to manual. This is considered important in reducing material wastage and improving consistency in the production of door frames.

It saves time as well because the machines reduce the actual time needed to make accurate cuts. They are much faster compared to hand saws, and that enables carpenters and woodworkers to finish projects in a shorter period. This advantage is great for businesses handling large volumes of door frames.

Industry reports from the U.S. Bureau of Labor Statistics show that automated woodworking equipment can increase the speed of cutting projects by up to 50% versus manual methods. This in turn enables companies to reduce labor costs and raise their level of production, thus finding these machines ideal for high-volume manufacturers.

Modern 45-degree cutting machines are equipped with user-friendly interfaces and intuitive controls, allowing access to both seasoned professionals and persons just starting their careers in the woodworking industry. Without long training, operators can orient themselves and optimize the operation process.

According to the Woodworking Technology Journal (2022), the adoption of digital control systems and touchscreen interfaces has reduced training time for operators by up to 40%, allowing for faster integration of new equipment into production workflows.

The best 45-degree cutting machines are extremely versatile, handling different sizes for various door frames-from the standard wood to the more complex metal frames. Other machines have an adjustable cutting angle that lets them perform beyond the standard 45-degree cuts and increases their utility across a wide array of projects.

Besides, modern machines are designed to handle various materials, such as steel, aluminum, and composite materials, besides wood, making the production of door frames more versatile. This is very helpful in commercial or custom-built projects where a wide variety of materials may be used.

Safety is paramount in any industry, and the 45-degree cutting machines are manufactured with safety features such as blade guards, emergency stop buttons, and anti-kickback. Such features reduce the possibility of accidents and make the environment a much safer place for your staff, ensuring that your firm also abides by the workplace safety legislation.

According to the Occupational Safety and Health Administration, the integration of safety features on machinery, including emergency stop and blade guards, can prevent workplace injuries by up to 30 percent in related woodworking operations.

Choosing the right 45-degree cutting machine is vital to getting the best results. Here are some key features to consider when evaluating options:

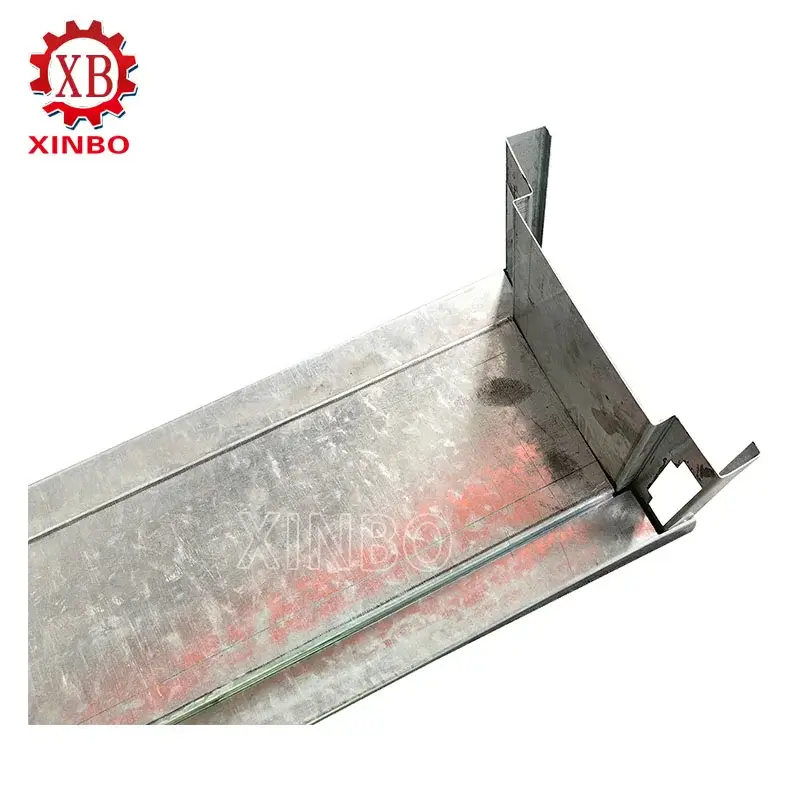

The cutting capacity refers to the maximum size of material the machine can handle. For door frame projects involving larger or thicker materials, it is important to choose a machine with an appropriate cutting capacity to meet those requirements.

In high-volume commercial production, cutting machines with a maximum cutting capacity of up to 200mm in material width are essential for handling larger frame sizes and thicker materials efficiently.

Motor power controls the speed and efficiency of cuts a machine will be able to make. Higher motor power will enable a machine to cut through thick or dense materials with ease. A higher rating given to a motor means there won’t be excessive strain on the motor, thus reducing wear over time, adding to the life of the machine itself.

In heavy-duty applications, the power ranges from 3-7KW depending on the thickness of the material and the difficulty involved in the cuts. The higher the rating of power, the more rigid materials such as steel or laminated wood that can be cut without compromising the quality of the cut.

The blade is one of the most important components in ensuring a clean and accurate cut. Carbide-tipped blades are highly recommended for their durability and sharpness. They offer long-lasting performance, especially when cutting tougher materials, such as composite wood or steel.

Carbide-tipped blades are well known for their superior performance in industrial settings, offering up to five times longer blade life than traditional steel blades. This is critical for maintaining cutting efficiency and ensuring consistent results throughout production runs.

Use a machine that has fine adjustments both for the angle and depth of cut; this will allow more precise cuts to suit your different door frame designs.

Industry reports from Woodworking Equipment Monthly, 2022, suggest that for professional-grade door frames with tight tolerances, the cutting depth and angle controls should be adjustable. The machines that set the angle digitally have improved the accuracy of the cut by up to 95%.

For example, the need to emphasize machines that are fully equipped with safety features such as blade guards, emergency stop buttons and anti vibration mechanisms. These not only ensure the safety of the operator but also minimize accidents and injuries.

NSC clarifies that incorporating anti-kickback devices integrated with automatic braking systems may reduce the number of accidents and injuries in the production floor by at least 25%.

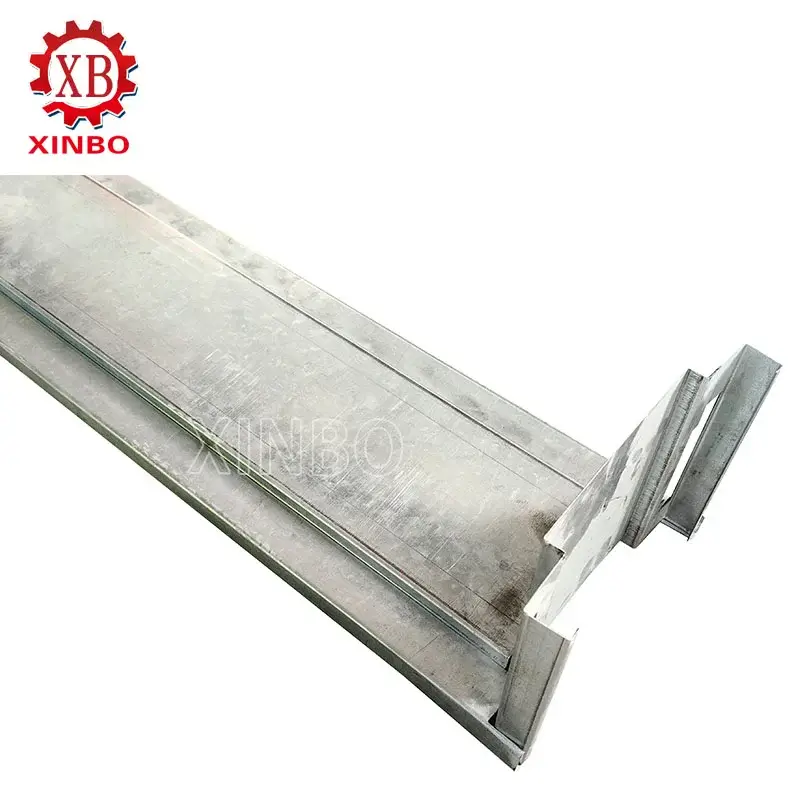

Among the quality and efficient woodworking solutions, the Door Frame 45 Degree Cutting Machine from Xinbo is outstanding. The Door Frame 45 Degree Cutting Machine targets professionals in the manufacturing of door frames and therefore assures accuracy and speed unparalleled, making it an irreplaceable tool for any workshop involved in the production of door frames.

Following is the detailed specification for Xinbo’s Door Frame 45 Degree Cutting Machine:

Xinbo’s cutting machine is designed with the capability to provide incredible accuracy in miter cuts for the smooth assembly of a door frame each time. It also houses intelligent design for ease of use and high customizability, hence a versatile tool for a variety of productions.

Make Connect Holes and Locker Holes: This machine can make accurate connect and locker holes, thus guaranteeing good door frame assembly and structural integrity.

Easy to Use: The user-friendly interface and intuitive controls minimize the learning curve and enable users to operate the cutting machine within the shortest time.

Intelligent Machine Design: It helps in optimizing performance and efficiency and smooth, precise cutting operations without compromising on quality, even when it comes to high volume.

Xinbo strives for offering qualitative machines that are compliant and meeting international standards. Machines were developed according to IEC standards to ensure reliability, efficiency, and long-lasting operation.

Moreover, Xinbo provides ODM services, which allow clients to design and build machines according to their needs. Such flexibility in the company means that businesses will always find exactly what they need for the production of door frames.

Xinbo also offers very good after-sales service that ensures customers

Receive ongoing support for maintenance, repair, and optimization. Their team is ready to answer technical queries, give advice, and assist in troubleshooting to ensure minimal downtime in production.

Carpenters, contractors, and manufacturers alike must ensure that the best 45-degree cutting machine is chosen to guarantee the accuracy, efficiency, and professionalism of door frames in production. Whether it be in wood, metal, or composite materials, a high-quality cutting machine investment such as Xinbo‘s ensures precision, speed, and consistency across your production process. This makes it the perfect addition to any workshop aiming for top-tier results and operational efficiency.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→