Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→The demand has been on the rise for serviceable, resistant, and less expensive building components in recent construction. In view of that fact, stud and track CU furring framing system has gained fast popularity because they are light but strong for such a wide field of construction use. The framing system basically includes C-shaped studs and U-shaped tracks that help in creating skeletal frameworks of various walls, floors, and ceilings. These are components that need such a high degree of precision and consistency during manufacture that the use of specialized machinery becomes quite essential, and that is where Stud and Track CU furring Framing Roll Forming Machines come in.

A Stud and Track CU Furring Framing Roll Forming Machine is a highly engineered and sophisticated piece of equipment to be used for converting steel coils into perfectly profiled, precision C- and U-profile sections used in systems for framing purposes. This includes continuity of handling, shaping, and cutting that is mostly coupled with punching and embossing of the continuous metal to bring forth each and every component precisely to specifications. The machine works on the principle of roll forming, where the metal is gradually bent and shaped while passing through a series of rollers.

The typical Stud and Track CU furring Framing Roll Forming Machine consists of several key components working in unison. These include uncoilers to hold and feed the metal coil, a number of roll-forming stands each with specially developed rollers that work the metal into shape, and a hydraulic system to cut formed profiles to correct lengths. This is often finished with an automated punching unit used for service holes or dimples. A PLC-based control system manages the process as a whole, thus giving precision and automation. The machine can also be fitted with a run-out table for collecting finished parts.

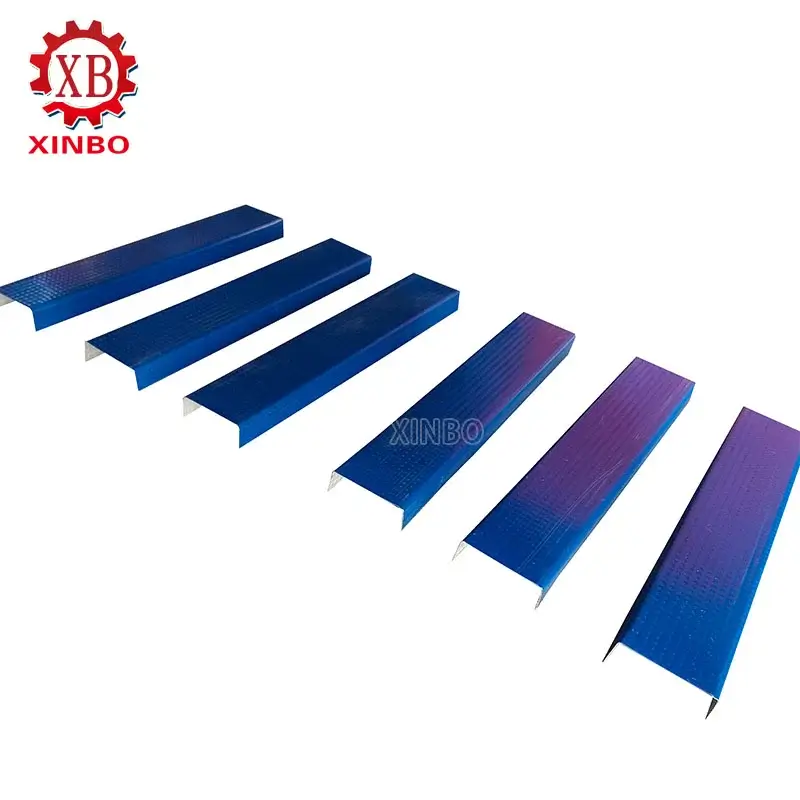

These machines are designed to work with various materials, typically GI or PPGI. Material thickness may be from a minimum of 0.3 mm to a maximum of 1.6 mm, depending upon the specific machine and application. The rollers are normally made of 45# steel with heat treatment and hard chrome plating, ensuring long service life under conditions of continuous work. During processing, the metal coil is fed through the machine, which gradually forms into the required ‘C’ or ‘U’ profile, cut to the set length. Moreover, the machines also provide the possibility to add your custom logo using embossing.

The investment in a Stud and Track CU furring framing roll forming machine can bring several benefits to the manufacturers and the construction projects where they are employed.

These are high-tech machines targeted at high-speed productions, with some of these machines able to make profiles at as high as 25-60 meters per minute. This level of automation cuts down any manpower requirements to the bone, increases output, and reduces project completion times. The continuous processing ensures consistency with very minimal downtimes.

Stud and Track CU furring Framing Roll Forming Machines can make highly accurate profiles. Advanced control systems ensure that every channel will be of the same dimension, thickness, and curvature. This accuracy cuts down on defects, reduces waste, and thus is important for quality, an essential factor for structural integrity.

Being automation machines, nature has made these machines very proficient in material use, adding more cost-effectiveness to manufacturing. This reduces materials wastage, hence reducing labour costs, translating to better profitability for a business while keeping its projects within an ideal budget framework.

These machines are very versatile, which can be configured to make many different profiles and sizes. Most suppliers provide the ability to customize their machines so that a manufacturer can create channels of specific dimensions, thicknesses, and hole patterns to suit various project needs. That is why such versatility in this stud and track CU furring framing roll-forming machine is an asset in so many applications.

The profiles by Stud and Track CU furring Framing Roll Forming Machines find applications across many sectors of construction.

The most common applications of these profiles are in wall, floor, and roof construction. The C studs and U tracks are required for the framing of drywalls and ceilings to provide a stable and strong platform for interior and exterior cladding. They are also applied in suspended ceiling grids.

The lightweight and precise nature of Stud and Track CU furring framing makes them ideal for modular and prefabricated building construction. These systems allow for efficient off-site manufacturing, which reduces on-site construction time and costs.

These profiles are used in making load-bearing frames for supporting roofs and floors in light commercial and residential projects. Because of its durability and strength, steel framing is a choice for many builders.

The versatility of these machines is that they can make special profiles for very specific uses, such as the frames of solar panels. The adaptability of the machines ensures that manufacturers can enter niche markets and specific project requirements.

Like all machinery, Stud and Track CU furring Framing Roll Forming Machines need regular maintenance to ensure longevity and optimal performance.

Cleanings are also vital to be able to clear this machine of accumulated dust, trash, or sometimes even metal shavings. Furthermore, the rollers and gears involved in the movements should be frequently lubricated so that the overall machine can operate with ease.

Regularly inspect the machine for any signs of wear and tear, damage, or misalignment. Periodically check the calibration of the machine to ensure that it is producing channels with the correct dimensions and tolerances.

Proper training for operators is crucial for the correct use and maintenance of the machine. Ensuring that operators are well-versed in the machine’s operation and safety protocols can minimize accidents and downtime.

Selecting the right Stud and Track CU furring Framing Roll Forming Machine is critical for maximizing efficiency and meeting production demands.

Before purchasing a machine, it’s essential to consider factors like the material you’ll be using, the required production volume, the specific profiles you need, and any customization requirements.

Look for suppliers who can prove a history of supplying good, reliable machines. Ask if technical support, training programs, and spare parts are available for the machine. A good supplier will provide comprehensive support to make sure your machine runs smoothly.

Xinbo is a highly recognized manufacturer in the field of metal shaping and roll forming machines. They have earned their prestige in offering the best quality, reliable, and innovative technology that meets various demands from customers. With an expert team comprising highly experienced engineers, technicians, and workers, Xinbo has made sure that Stud and Track CU furring Framing Roll Forming Machines are designed and fabricated to perfection. Besides, the company is in a position to customize products according to specific customers’ requirements.

Xinbo demonstrates its commitment to quality through their rigorous inspection process, conducting numerous quality checks prior to shipping a machine to ensure that each unit meets the exact specifications. Because of this drive for innovation, quality, and customer satisfaction, Xinbo remains a trusted business partner in every investment in cutting-edge roll-forming technology. Xinbo’s machines are also designed to easily fit into a standard shipping container, making international shipping more economical.

Stud and Track CU furring framing roll-forming machines are very important for effective and accurate production of important elements in contemporary building. Their advantages include high speeds, constant quality, versatility, and reasonable price. These machines will find applications in everything from the construction of residential and commercial buildings to more specialized applications like modular homes and solar panel frames.

Proper maintenance and care are crucial for the longevity of the machines, and choosing a good supplier like Xinbo will ensure that the investment is reliable and long-term. With the right Stud and Track CU furring Framing Roll Forming Machine, businesses can significantly enhance their production processes and meet the ever-growing demands of the construction industry.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→