Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→This blog presents a detailed explanation of the metal photo frame panel making machine, or roll forming machine for metal photo frames in the industry. It presents its definition, working principle, components, advantages, selection criteria, and realistic installation, operation, and maintenance requirements. The content is written to be informative to both industry professionals and hobbyists, in the hopes of achieving a complete knowledge of this essential equipment.

The metal photo frame panel making machine is a dedicated machine used to produce panels for metal photo frames, which are in common use for decoration. This section provides a definition of the machine and its significance in the market.

This machine is also known as a roll forming machine and folds flat metal sheets, such as steel or aluminum, into specific cross-sections for photo frame borders. It employs a roll forming process by which the metal is progressively folded by passing through a series of rolls, keeping precision and uniformity intact. These profiles are then cut to length and molded into frames and hence are ideally suited for decorative purposes.

Metal picture frames are also trendy in modern interior design due to their elegance and longevity, driven by a need for high-end decorative items. The roll forming machine allows for quick, high-volume production that meets market needs at reduced costs. Its high-volume production of uniform-looking, visually appealing frames makes the machine an industry standard for manufacturers who want to supply the residential and commercial decoration industries.

Roll forming is the primary process utilized by the metal photo frame panel making machine, and this subtopic explains its principle and application in photo frame production.

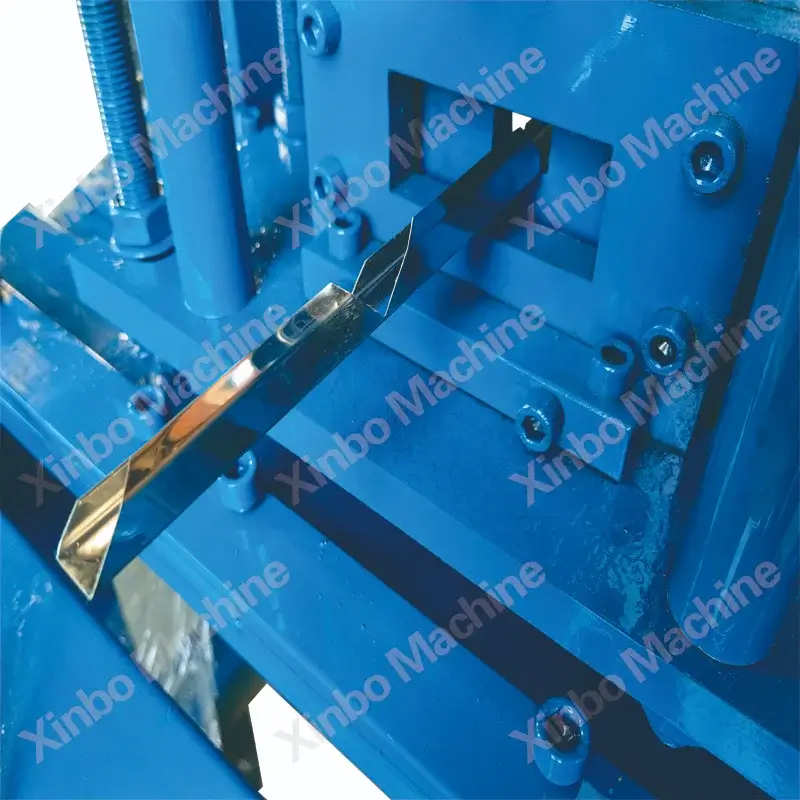

Roll forming is a cold forming process through which a flat metal strip is fed through a succession of roll stands, each of which has top and bottom rolls that gradually form the metal into a specific cross-section. It is not like bending or stamping since it is continuous, preserves the properties of the metal, and minimizes waste, thus suitable for long, uniform profiles.

Roll forming in photo frame manufacturing creates the accurate profiles used for frame edges, such as channels or decorative shapes. Roll forming ensures precision and consistency, which is paramount for frames that must fit accurately. The process functions best when long runs of the same quality are needed, meeting the looks and performance requirements of decorative frames.

The roll forming machine has a series of principal components that all play a basic part in the production process. This page outlines these components and how they function.

Uncoiling Station:The uncoiling station holds the metal sheet, typically in coiled shape, and feeds it to the machine at a controlled rate. For photo frame making, it has to accommodate particular widths and thicknesses, such as aluminum or steel, in order to create a steady feed for equal forming.

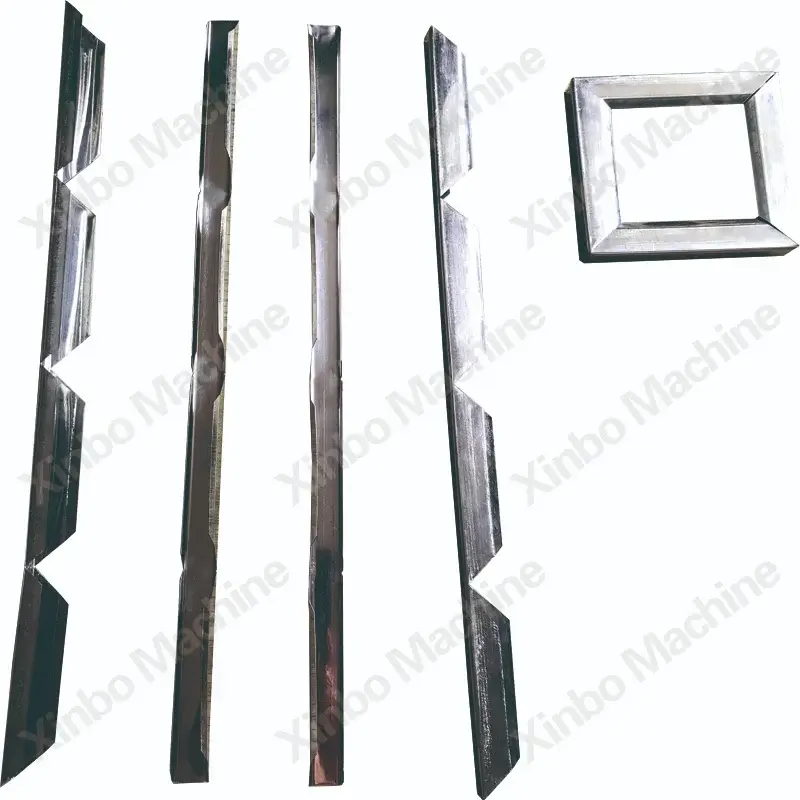

Roll Forming Station:This is the heart of the machine, that is, a series of roll stands that increasingly shape the flat metal into the required shape. In photo frames, the rolls are designed to create specified cross-sections, such as rectangular channels or decorations, in order to maintain the frame’s value and strength.

Punching and Cutting Mechanism:Others have a punching and cutting feature to punch holes or cut the formed profile to length. In photo frame production, punching can create hanging holes or assembly points, while cutting enables each frame section to be the correct length to assemble, making it more efficient.

Control System:The control system controls the machine functions, including roll speed, pressure, and automated features. It typically utilizes a programmable logic controller (PLC) or computer interface to achieve uniform quality and reduce manual intervention, critical for high-volume production.

Roll forming machines utilized in metal photo frame panels benefit from many advantages, making them a favorite choice within the industry.

Since roll forming is a continuous operation, it allows for the mass production of long profiles at a high rate of speed, ideal for meeting bulk orders. It is crucial to producers with scarce time and vast quantities of orders to make prompt delivery.

Compared to other shape-forming processes like stamping, roll forming generates less scrap, utilizing the metal sheet efficiently. This is cost-effective for materials and supports green manufacturing practices that appeal to green companies.

Design Versatility:The machine can produce a variety of profile shapes by changing rolls, from geometric forms to complex ornamental designs. Such flexibility enables manufacturers to create varied frame styles, meeting different looks preferences and prevailing fashions, thus enhancing competitiveness.

The choice of the right roll forming machine is a thoughtful selection of several factors to ensure that the machine is adequate for production needs and operating performance.

Identify how much output is required, i.e., how many an hour, and select a machine with capacity to deliver or surpass this need. Identify if the machine can handle multi-shift operation to optimize use of peak demand time.

There have been designed various machines that work smoothly with particular metals, i.e., steel or aluminum, and thicknesses. Ensure that the chosen machine has the capability to work with the desired material and thickness in order to achieve forming quality and durability, reducing potential operating issues.

Considering Automation and Control Features:New equipment generally includes automation features like automatic lubrication, tension adjustment, and simplicity of use. These render them more productive, reduce labor costs, and minimize errors, which makes them perfectly suitable for uninterrupted, large-scale use.

Installation, operation, and maintenance are crucial to get the maximum production and machine longevity. This page is packed with informative details about all three.

Installation requires adequate space, power, and air flow, as indicated by the manufacturer. Install equipment on firm, level ground, earthed, and with correct voltage to prevent technical issues.

Machine operation involves staff training to feed the metal sheet, profile parameter adjustment, and process control. Safety is never compromised, with protective equipment, gloves, and goggles on the operator, and hands away from moving parts. Integrated quality control, with check monitoring to ensure shaped profiles meet dimensional and aesthetic specifications.

Maintenance is performed at regular intervals to avoid litter, lubricate the moving parts to minimize wear and tear, and inspect pieces like rolls and cutters for damage. Adhering to the recommended schedule by the manufacturer allows the machine to function for a long time and operate without any problems, minimizing downtime.

Troubleshooting Common Issues:Typical problems are roll misalignment, tool wear, or control system failure. For instance, for skew profiles, check roll alignment; for system failure, restart the machine or contact technical support. A maintenance contract and troubleshooting routine with the manufacturer would be preferable to reduce downtime and maximize utilization.

This manual offers a detailed explanation of the metal photo frame panel producing machine in light of its contribution to effective and high-quality production. Its components, advantages, and working conditions can assist manufacturers in selecting, installing, and maintaining the suitable machine to accommodate market needs. As there is further expansion in the decoration industry, further advancement in automation and environmental protection can improve these machines with even better efficiency and protection of the environment.

Need a metal photo frame panel making machine? Xinbo, experienced roll forming machine supplier, can supply customized products according to your own specifications. Our machines are able to make high-quality metal photo frame panels at high efficiency. Over 10 years’ experience ensures us to be committed to quality and reliability. Inquiry for price with us.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→