4 Key Advantages of Sheet Metal Forming Process

Introduction to Sheet Metal Forming Process

Sheet metal forming is a widely utilized manufacturing process that involves shaping metal sheets into the desired form. This process is highly popular in the manufacturing industry due to its versatility and cost-effectiveness. The global sheet metal market has been steadily expanding, with a continuous average growth rate of 4.09% from 2018 to 2022, indicating its significant impact on various industries.

The process of sheet metal forming enables the production of complex components that cannot be formed through conventional room temperature metal forming processes. Recent developments in this field focus on emerging forming techniques to produce parts with non-traditional operations, emphasizing design and material innovation. Additionally, advancements in technology have allowed for better analysis and understanding of sheet metal materials, structure, forming forces, and limits.

One of the key reasons why sheet metal forming is popular in manufacturing is its ability to adapt to custom requirements and complex designs. This flexibility allows businesses to meet specific needs and create tailored solutions for their customers. Moreover, the economic benefits associated with this process are substantial. The North American sheet metal fabrication equipment market is anticipated to reach USD 11.9 billion by 2030, showcasing its growing importance in the industry.

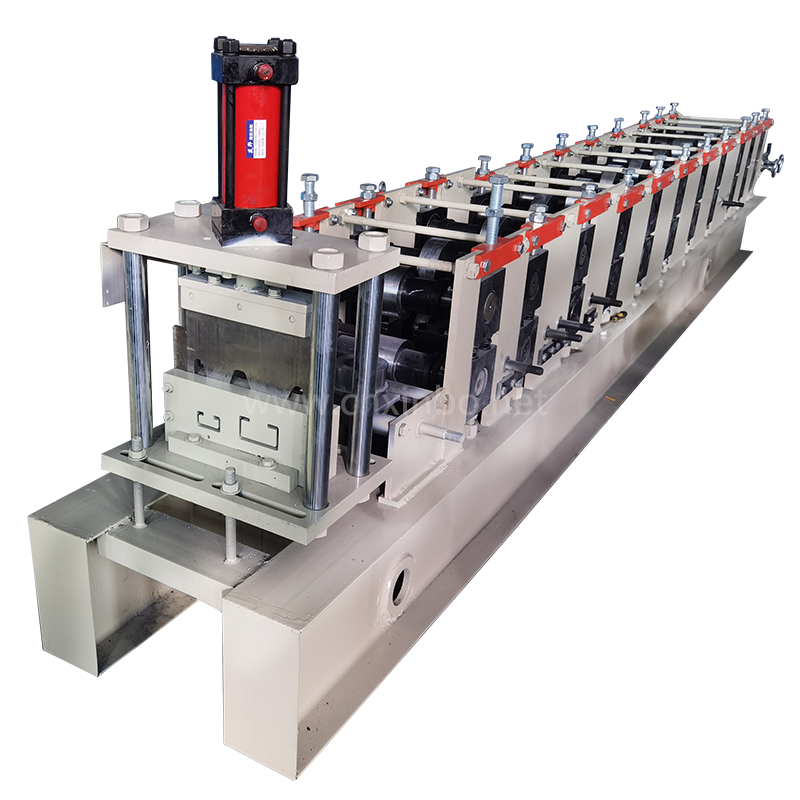

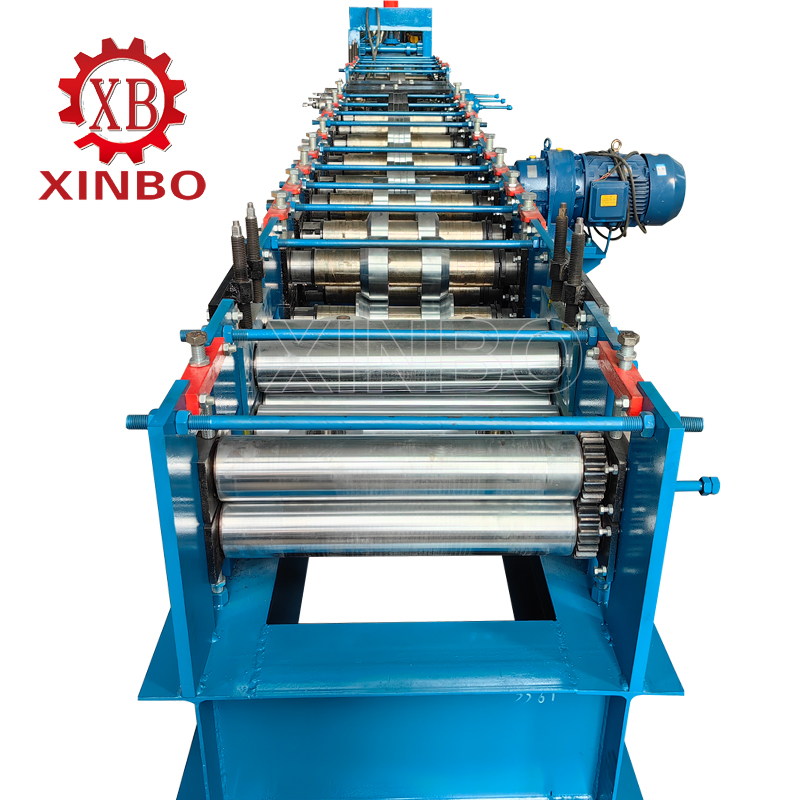

Xinbo, a manufacturer established in China since 2014, specializes in providing machines that aid in sheet metal forming process. One of the machines Xinbo offers is the U channel rolling forming machine. This machine is capable of rolling metal sheets into U-shaped channels of different sizes and thicknesses. It is equipped with advanced technology and features that enable it to perform various tasks seamlessly. The machine is highly adjustable, allowing for easy customization according to specific requirements.

The current focus on enhancing operational efficiency and lean manufacturing has significantly contributed to increased demand for sheet metal forming among OEMs (Original Equipment Manufacturers). This trend aligns with the global efforts towards energy reduction in manufacturing processes, further driving research efforts towards innovative sheet metal forming techniques.

1. Cost-Effectiveness

Sheet metal forming offers significant cost-effectiveness, making it a preferred choice for manufacturers seeking efficient production processes. The low tooling and operation costs associated with sheet metal forming set it apart from other manufacturing processes, contributing to its widespread adoption in various industries.

Low Tooling and Operation Costs

When comparing sheet metal forming with other manufacturing processes, the cost advantages become evident. Unlike traditional methods that often require expensive tooling and equipment, sheet metal forming minimizes the need for complex machinery, resulting in lower initial setup costs. This reduction in tooling expenses directly impacts the overall production cost, allowing businesses to allocate resources more efficiently.

Economic Benefits for Businesses

The economic advantages of sheet metal forming extend beyond initial cost savings. By reducing waste and maximizing efficiency, businesses can achieve substantial long-term benefits. Real-world case studies highlight the tangible impact of adopting sheet metal forming on cost reductions and manufacturing improvements.

In addition to reducing operational costs, sheet metal forming supports lean manufacturing principles by streamlining production processes and minimizing material wastage. This approach aligns with industry efforts towards sustainable practices while enhancing profitability for businesses.

Advantages:

·Lower tooling and operation costs

·Economicbenefits for businesses

2. Design Flexibility

Sheet metal forming offers unparalleled design flexibility, allowing manufacturers to create complex and customized parts with ease. This section explores how sheet metal forming adapts to intricate designs and meets custom requirements, showcasing its pivotal role in modern manufacturing.

Adapting to Complex Designs

Examples of Complex Parts Made Easy

In the realm of sheet metal forming, intricate designs that were once deemed challenging are now achievable with precision and efficiency. Designers and Engineers attest to the remarkable transformation of complex part production through innovative sheet metal forming techniques. The ability to fabricate intricate geometries, such as convoluted shapes and multi-dimensional components, demonstrates the exceptional design adaptability of this process.

The utilization of advanced machinery and computer-aided design (CAD) software has revolutionized the way complex parts are manufactured. By leveraging these technological advancements, manufacturers can seamlessly translate intricate design specifications into tangible products, thereby expanding the possibilities for creative and functional applications.

The Role of Modern Technology

Modern technology plays a pivotal role in enhancing design flexibility within the sheet metal forming process. Computer simulations enable designers and engineers to visualize and analyze the behavior of materials under different forming conditions, ensuring optimal outcomes for even the most complex designs. Furthermore, the integration of additive manufacturing techniques has opened new frontiers for creating intricate features within sheet metal components, further amplifying their functionality and aesthetic appeal.

Meeting Custom Requirements

How Sheet Metal Forming Supports Customization

One of the key advantages of professional Sheet Metal Fabrication Design Services is their ability to tailor solutions to specific project needs. Each project is unique, requiring a bespoke approach to design that considers factors like material choice, thickness, and production volume. Designers collaborate with clients to understand their goals, translating ideas into designs that balance form and function.

The customization capabilities inherent in sheet metal forming empower businesses to address diverse customer demands effectively. From personalized enclosures for electronic devices to intricately designed automotive components, sheet metal forming enables manufacturers to realize custom requirements without compromising on quality or efficiency.

By embracing a customer-centric approach facilitated by sheet metal forming capabilities, businesses can differentiate themselves in competitive markets while fostering long-term partnerships based on trust and reliability.

3. Durability and Strength

Sheet metal forming offers unparalleled durability and strength, making it a preferred choice for manufacturing robust components across various industries. The resilience of sheet metal parts is attributed to their material properties and environmental resistance, as well as their exceptional performance in harsh conditions.

The Resilience of Sheet Metal Parts

Material Properties and Environmental Resistance

Sheet metal fabrication offers high strength relative to weight, high electrical conductivity, cost-effectiveness, and enhanced operational efficiency when compared to other materials. Steel, in particular, outperforms aluminum, iron, and titanium in tensile strength, further solidifying its position as a durable and robust material for sheet metal forming processes. This inherent strength makes sheet metal fabrication an ideal prototyping and production process for creating strong functional parts like panels, brackets, and enclosures.

Real-world applications demonstrate the durability of sheet metal parts across diverse environments. From automotive body panels to aerospace components, sheet metal parts consistently showcase exceptional resilience under varying environmental conditions. Their ability to withstand corrosion, impact forces, and temperature fluctuations underscores their reliability in demanding operational settings.

Benefits in Harsh Conditions

Case Examples in Extreme Environments

In extreme environments such as marine or aerospace applications, the durability of sheet metal parts becomes particularly evident. For instance, marine-grade stainless steel fabricated through sheet metal forming processes exhibits remarkable resistance to corrosion from saltwater exposure. This unique characteristic ensures the longevity of critical components in maritime vessels while minimizing maintenance requirements.

Similarly, within the aerospace industry, sheet metal components endure rigorous conditions during flight operations. Their ability to maintain structural integrity under high-stress situations contributes significantly to the overall safety and reliability of aircraft systems. The lightweight yet durable nature of these components enhances fuel efficiency without compromising on strength or performance.

Longevity and Maintenance Advantages

The longevity of sheet metal parts translates into substantial maintenance advantages for various applications. Unlike alternative materials that may require frequent repairs or replacements due to wear and tear, sheet metal components offer extended service life with minimal maintenance needs. This characteristic reduces downtime associated with maintenance activities while ensuring consistent operational performance over prolonged periods.

Furthermore, advancements in surface treatment technologies have further enhanced the durability of sheet metal parts by providing additional protection against environmental degradation. These treatments include corrosion-resistant coatings that bolster the material’s innate resistance to external elements while prolonging its lifespan.

4. Precision and Accuracy

Precision and accuracy are paramount in the sheet metal forming process, ensuring high-quality standards that meet the rigorous demands of modern manufacturing. The techniques employed to achieve precision play a pivotal role in elevating the overall quality of sheet metal components, while the importance of accuracy cannot be overstated, especially in critical applications.

Achieving High-Quality Standards

Techniques Ensuring Precision

Innovative techniques such as computer-aided manufacturing (CAM) and numerical control (NC) machining have revolutionized precision in sheet metal forming. These technologies enable manufacturers to meticulously control the cutting, bending, and shaping processes with unparalleled accuracy. By leveraging CAM and NC machining, intricate designs can be translated into precise physical components, ensuring consistency and adherence to exact specifications.

Furthermore, advancements in laser cutting technology have significantly enhanced the precision of sheet metal fabrication. Laser cutting allows for intricate patterns and complex geometries to be achieved with exceptional accuracy, contributing to the production of high-quality parts across various industries. The ability to precisely cut and shape sheet metal materials has expanded the possibilities for innovative designs while maintaining strict dimensional tolerances.

Importance of Accuracy in Critical Applications

In critical applications such as aerospace engineering and medical device manufacturing, accuracy is non-negotiable. The slightest deviation from specified dimensions or tolerances can have far-reaching implications on performance and safety. Sheet metal forming processes must uphold stringent accuracy standards to ensure that components function reliably within these critical environments.

The integration of advanced metrology systems enables manufacturers to verify the dimensional accuracy of sheet metal parts with meticulous detail. This ensures that each component meets precise specifications, aligning with industry regulations and quality assurance protocols. The emphasis on accuracy not only guarantees compliance with technical requirements but also instills confidence in end-users regarding the reliability and performance of sheet metal products.

The Impact on Industry Standards

Setting New Benchmarks for Quality

The relentless pursuit of precision and accuracy within sheet metal forming has set new benchmarks for quality across diverse sectors. As manufacturers continue to refine their processes through technological advancements, they raise the bar for industry standards by delivering components with unparalleled precision and dimensional stability.

Testimonials from industry leaders underscore the transformative impact of precision-driven sheet metal forming processes on product quality. These accounts highlight how meticulous attention to detail has elevated the performance and reliability of components across automotive, aerospace, electronics, and other key industries. By consistently achieving exceptional levels of precision, manufacturers are redefining what constitutes high-quality sheet metal products.

In addition to meeting existing standards, these advancements have paved the way for evolving regulatory frameworks that recognize the significance of precision in manufacturing practices. Industry-wide recognition of precision as a cornerstone for product excellence reinforces the commitment towards continuous improvement while fostering trust among stakeholders.

Conclusion

In conclusion, the sheet metal forming process offers unparalleled advantages in modern manufacturing, encompassing cost-effectiveness, design flexibility, durability, and precision. The diverse applications of sheet metal forming underscore its pivotal role in shaping various industries and driving innovation.

Recap of Key Points

Throughout this blog, we have delved into the multifaceted benefits of sheet metal forming. From its cost-effective nature to its ability to meet custom requirements and withstand harsh conditions, the process stands as a cornerstone of efficient and reliable manufacturing. The emphasis on precision and accuracy further solidifies its position as a preferred choice for creating high-quality components across diverse sectors.

The Future of Sheet Metal Forming

As technology continues to evolve, the future of sheet metal forming holds promising innovations that will further enhance its capabilities. Emerging advancements in material science, additive manufacturing techniques, and digital simulations are poised to revolutionize the way sheet metal components are designed and produced. These innovations on the horizon are set to elevate the efficiency and sustainability of sheet metal forming processes while expanding the scope of complex part fabrication.

Innovations on the Horizon

The integration of smart manufacturing technologies is expected to streamline production processes within sheet metal forming, optimizing resource utilization and reducing lead times. Additionally, advancements in material research will pave the way for enhanced material properties that offer superior strength-to-weight ratios and environmental resilience. These developments will not only redefine traditional manufacturing practices but also open new avenues for creating innovative products with unprecedented performance characteristics.

Final Thoughts on Its Growing Importance

In light of these advancements, it is evident that sheet metal forming’s growing importance transcends conventional manufacturing paradigms. By embracing technological progress and leveraging design flexibility, durability, precision, and cost-effectiveness inherent in this process, manufacturers can unlock new possibilities for product innovation and operational excellence.

In essence, as industries continue to evolve in response to changing market demands and sustainability imperatives, sheet metal forming remains an indispensable asset for realizing creative designs with exceptional functionality.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia