How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

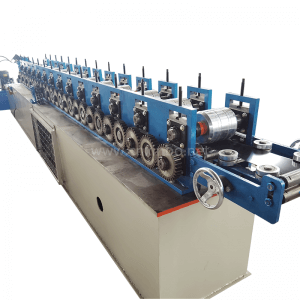

Keel roll forming machine

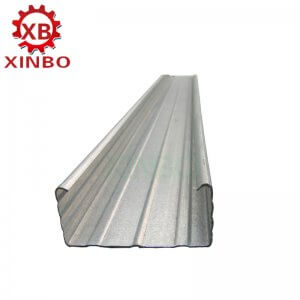

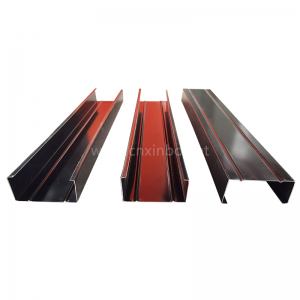

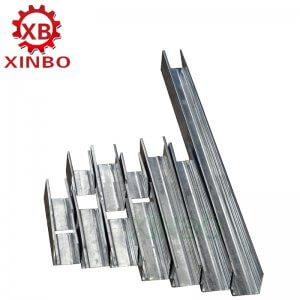

Keel machine takes strip steel as raw material, through continuous cold rolling forming, to produce complex sectional profile products. The keel machine is mainly composed of three parts: the filling steel plate, the forming and the post forming cutting. The appearance of the products manufactured for pressing the tiles meets the requirements of bright appearance, texture scratch, high strength and long service life. Its application areas are especially large, such as factory decoration, warehouse cage The roofs and new walls of the locomotive hangar are all made of the corresponding products used to press the tiles. The products used to press the tiles are leftovers determined to be used for the decoration of the steel structure workshop. The main equipment, computer control system, hydraulic pump and automatic post shearing equipment are the major components of the keel synthesis machine. The keel machine parts adopt high-level automatic control software, so the manufacturing information management. The keel machine also has the advantages of operation tutorial, maintenance, regular maintenance, equipment debugging, easy mold replacement, etc.

|

No. |

Item |

Specification |

|

1. |

Processing Material |

GI.Black steel.Al |

|

2. |

Input Width(mm) |

As designing |

|

3. |

Formed Width(mm) |

As customer drawings |

|

4. |

Processing Thickness(mm) |

0.8-1.2mm |

|

5. |

Material of Rollers |

45# steel,with hard chrome coated |

|

6. |

Diameter of Shaft |

Ф70-80mm |

|

7. |

No.of rollers |

13 |

|

8. |

Production Speed |

0-15m/min |

|

9. |

Roller Driven |

Decelerating Motor+gear+Chain Transmission |

|

10. |

Cutting Model |

Hydraulic Profile Cutting |

|

11. |

Length Measurement |

Encoder |

|

12. |

Control Style |

PLC |

|

13. |

Operation Model |

Button+ screen |

|

14. |

Total Power |

5.5KW |

|

14. |

Voltage |

380V 50HZ or at buyer’s request |