How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

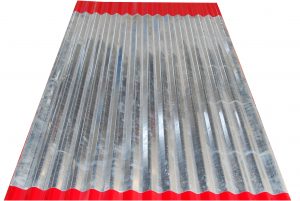

Produce hard and very thin materials.

Easily to operate.

Having the forward and backward parts. workers put into the flatter plates and get the corrugated plates on another side. very easy to use.

Popular for Philippines and Africa market.

1.Processing flow:

Pre-cut material sheet–feeding platform–forming–pinch rollers–receiving table

|

Item |

|

|

|

1. |

Power supply |

380V, 50Hz, 3 phrases or at buyer’s requirement |

|

2. |

Feeding width |

1200mm |

|

3. |

Formed width |

760mm |

|

4. |

Material |

thin galvanized sheets |

|

5. |

Material thickness |

0.14mm TO 0.30mm |

|

6. |

Material length |

Max 3600MM |

|

7. |

Power |

11kw |

|

8. |

Diameter Of corrugation rolls |

380mm*2 pieces |

|

9. |

Diameter Of pinch rolls |

340mm*2 pieces |

|

10. |

Barrel Length |

3600 MM |

|

11. |

Speed |

15–18 strokes/min(can be adjusted by pulley) |

|

12. |

Productivity |

30–36 sheets from 0.14–0.20mm 15–18 sheets from 0.22–0.30mm |

Detailed illustration of the corrugation machine

|

1. |

Driven system |

It is driven by an A.C. motor through a gear reduction drive train |

|

2. |

Pinch rollers |

It is driven by a chain&sprocket drive arrangement through both the corrugation rollers |

|

3. |

Feed platform |

With gauge blocks to adjust the sheet width; it can slides according to actual need. It is adjust by crank. |

|

4. |

Tensiometer arrangement |

It is fixed on the housing to tighten the chains. Please see photos as below. |

|

5. |

Exit table |

It is set to receiving and supporting the corrugation sheets. |

This producing line is maintained free of charge for 18 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians travelling abroad.