How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

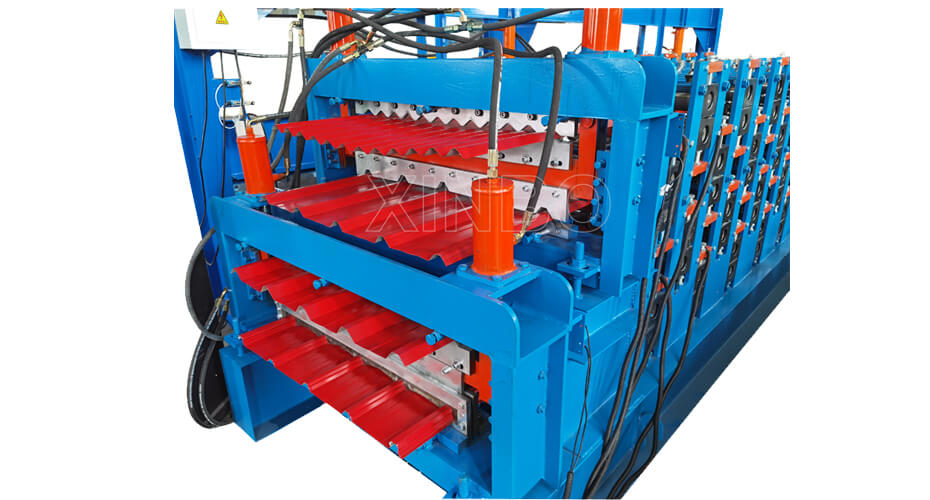

Four Layer Roof Sheet Roll Forming Machine

Four-layer roofing sheet roll forming machine is a specialized equipment designed to produce roofing sheets with multiple layers of material. This machine utilizes advanced roll forming technology to create sheets that are not only robust but also aesthetically pleasing. The four layers typically consist of a base layer for structural support, insulation material for thermal efficiency, a decorative layer for visual appeal, and a protective layer for weather resistance.

Technical Specifications of this four layer roof sheet roll forming machine

| Processing Material | PPGI, GI, Aluminium, zinc coils |

| Input Width | 914mm/925mm/1000mm/1200mm/1220mm/1250mm/customized |

| Formed Width | As drawings/needing |

| Processing Thickness | Standard: 0.3—0.7mm/customized |

| Frame Style | 350mm H steel welded |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 70mm |

| Production Speed | Standard: 0–15m/min; customized |

| Roller Driven | Decelerating Motor+China Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 4+4KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

Company Certificates