How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

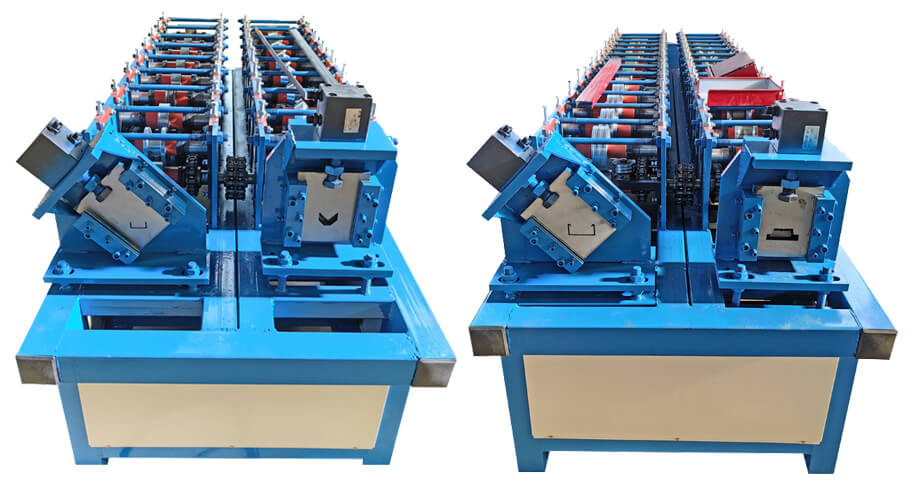

Dual Running CU Channel Roll Forming Machine

A CU Channel Roll Forming Machine is a specialized machine that shapes flat metal strips into CU channels through a series of rollers. The process involves feeding the metal strip into the machine, where it passes through a sequence of rollers that progressively bend and shape the material into the desired channel profile. The roll forming process is known for its efficiency, allowing for continuous production with minimal waste.

Technical Specifications of this keel roll forming machine

| Processing Material | GI coils |

| Input Width | customized |

| Formed Width | as needing |

| Processing Thickness | Standard: 0.3—0.6mm |

| Frame Style | Steel plate welded box |

| Material of Rollers | 45# steel, with heat treatment and hard chromed |

| Diameter of Shaft | 50mm |

| Production Speed | Standard: 0–25m/min(without punching); customized |

| Roller Driven | Gear Transmission |

| Cutting Model | Hydraulic Profile Cutting |

| Length Measurement | Encoder |

| Control Style | PLC |

| Operation Model | Button+Touch Screen |

| Total Power | 4+4+1.5KW; customized |

| Voltage | 380V, 50Hz, 3 phrases; or at buyer’s request |

Company Certificates