How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

Floor Deck Roll Forming Machine

The decoiler is used to hold and feed the raw material into the machine. The feeding unit is responsible for feeding the raw material into the roll forming unit. The roll forming unit is where the raw material is formed into the desired shape. The hydraulic cutting unit is used to cut the formed material into the required length. The control system is responsible for controlling the entire operation of the machine.

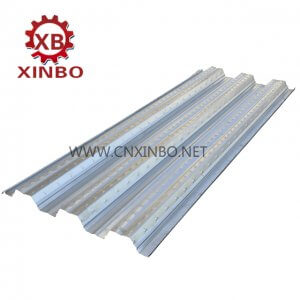

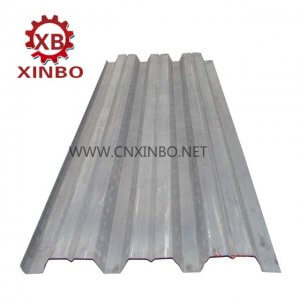

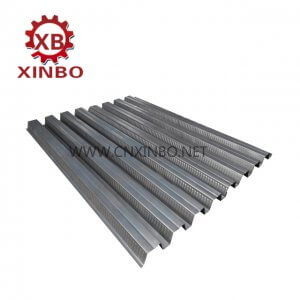

The Floor Deck Roll Forming Machine can produce different types of floor decking panels, including corrugated sheets, trapezoidal sheets, and other customized shapes. The thickness of the sheets can also be adjusted according to the customer’s requirements.

|

ITEM |

SPECIFICATION |

|

Processing Material |

GI |

|

Input Width(mm) |

1000 |

|

Formed Width(mm) |

688 |

|

Processing Thickness(mm) |

0.8—1.0 |

|

Material of Rollers |

45# steel,with hard chrome coated |

|

Diameter of Shaft |

Ф80mm |

|

Production Speed |

8—10m/min |

|

Roller Driven |

Decelerating Motor+Chain Transmission |

|

Cutting Model |

Hydraulic Profile Cutting |

|

Length Measurement |

Encoder |

|

Control Style |

PLC |

|

Operation Model |

Button + Touch Screen |

|

Total Power |

11+11+5.5KW |

|

Voltage |

380V 50HZ or at buyer’s request |

|

Number of roller stations |

26 or as designing |