How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

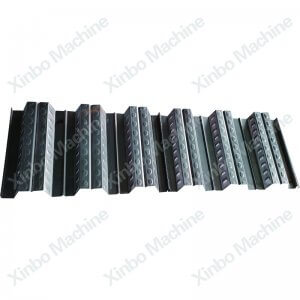

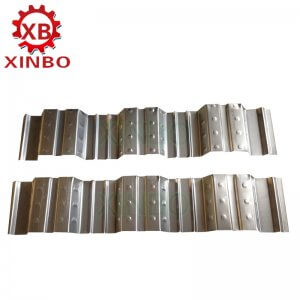

Decking floor roll forming machine

The steel floor bearing plate produced by this machine has simple shape, large waviness, high strength, and good adhesion after being paved with spot welded reinforcement mesh and combined with concrete pouring on site during installation. In high-rise buildings, the steel formwork can be omitted and the floor bearing capacity can be reduced. On the premise of reaching the same bearing capacity, the amount of steel used in the project can be reduced to save investment.

Characteristics of floor bearing plate:

1. Light weight, high strength, large bearing capacity and good seismic resistance;

2. Simple and fast construction and convenient assembly;

3. Replace the traditional formwork and improve its shortcomings;

4. It can be used as a part of structural strength to reduce material cost;

5. Easy construction of reinforcement, wiring and piping;

6. The appearance is neat and beautiful.

|

Item |

Specification |

|

Processing Material |

GI |

|

Input Width(mm) |

1000 |

|

Formed Width(mm) |

688 |

|

Processing Thickness(mm) |

0.8—1.0 |

|

Material of Rollers |

45# steel,with hard chrome coated |

|

Diameter of Shaft |

Ф80mm |

|

Production Speed |

8—10m/min |

|

Roller Driven |

Decelerating Motor+Chain Transmission |

|

Cutting Model |

Hydraulic Profile Cutting |

|

Length Measurement |

Encoder |

|

Control Style |

PLC |

|

Operation Model |

Button + Touch Screen |

|

Total Power |

11+11+5.5KW |

|

Voltage |

380V 50HZ or at buyer’s request |

|

Number of roller stations |

26 or as designing |